[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9

[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9

wehewehe

AIKIPane

AIKIHua'ōlelo

AIKIHāʻawi

MAKAUKAU E HOOKAPU

10000+ SKU i loko o kahi waihona

Hāʻawi mākou i nā mea RTS:

70% nā mea i hāʻawi ʻia i loko o 5 mau lā

80% nā mea i hāʻawi ʻia i loko o 7 lā

90% nā mea i hāʻawi ʻiai loko o 10 lā

Nā kauoha nui, e ʻoluʻolu e kelepona i ka lawelawe mea kūʻai aku

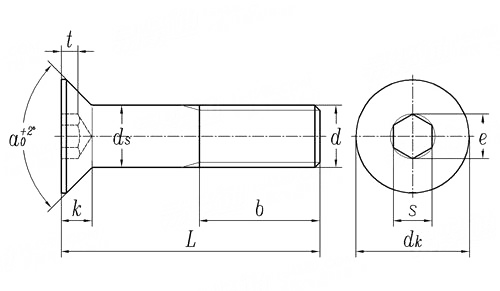

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Nominal | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Nominal | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Nominal | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Nominal | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

wehewehe kikoʻī

ʻO nā mea hoʻopaʻa ikaika kiʻekiʻe e hana i ka crispness i ka wā i hoʻopaʻa ʻia.Pono ka nānā kūikawā.

Hōʻike pinepine ʻia ka embrittlement hydrogen e ka haʻi lohi ma lalo o ke kaumaha.Aia nā pūnāwai kaʻa, nā mea holoi, nā ʻili, nā puna wai a me nā ʻāpana galvanized ʻē aʻe, i loko o kekahi mau hola ma hope o ka haki ʻana o ka hui, ʻo ka haʻihaʻi o 40% ~ 50%.Ma ke kaʻina hana o ka hoʻohana ʻana i nā ʻāpana cadmium-plated o kahi huahana kūikawā, aia nā ʻāpana ʻōpala, a ua hoʻoholo ʻia kahi pilikia kī kī aupuni a ua hoʻokumu ʻia kahi kaʻina dehydrogenation koʻikoʻi.Eia kekahi, aia kekahi mau hydrogen embrittlement ʻaʻole hōʻike i ka lohi ʻana o ka haki ʻana, e like me: electroplating hanger (steel wire, copper wire) ma muli o nā manawa he nui o ka electroplating a me ka pickling plating, ʻoi aku ka koʻikoʻi o ke komo ʻana o ka hydrogen, ʻike pinepine ʻia i ka hoʻohana ʻana i kahi paʻi. hiki mai ke ano hakihaki;ʻO ka mandrel o kahi pū pana, ma hope o kekahi mau manawa o ka chroming, hāʻule i ka honua a haki;ʻO kekahi mau ʻāpana kinai (ke koʻikoʻi kūloko nui) e pohā i ka wā pickling.Hoʻohana nui ʻia kēia mau ʻāpana me ka ʻole o ke koʻikoʻi o waho, ʻaʻole hiki ke hoʻohana hou ʻia e hoʻihoʻi i ka paʻakikī kumu ma o ka dehydrogenation.

ʻO ke kiʻekiʻe o ka ikaika waiwai, ʻoi aku ka nui o ka naʻau o ka hydrogen embrittlement.He manaʻo kumu kēia e pono e wehewehe ʻia e nā ʻenehana lapaʻau i ka wā e hōʻuluʻulu ai i nā kikoʻī kaʻina hana electroplating.ʻO nā kila me ka ikaika tensile σb>105kg/mm2 i koi ʻia e nā kūlana honua pono e hoʻokau ʻia i ke koʻikoʻi pre-plating a me ka mālama dehydrogenation post-plating e like me ia.Pono ka ʻoihana mokulele Farani i ka mālama dehydrogenation kūpono no nā ʻāpana kila me ka ikaika hua σs>90kg/mm2.

Ma muli o ka pilina maikaʻi ma waena o ka ikaika kila a me ka paʻakikī, ʻoi aku ka intuitive a maʻalahi hoʻi e hoʻokolokolo i ka naʻau hydrogen embrittlement o nā mea ma ka paʻakikī ma mua o ka ikaika.No ka mea, pono ke kaha ki'i huahana a me ka hana machining me ka paakiki kila.I ka electroplating, ua ʻike mākou ua hoʻomaka ka paʻakikī o ke kila a puni ka HRC38 e hōʻike i ka pilikia o ka haki ʻana o ka hydrogen embrittlement.No nā ʻāpana kiʻekiʻe aʻe ma mua o HRC43, pono e noʻonoʻo ʻia ka dehydrogenation ma hope o ke kau ʻana.Ke pili ka paʻakikī i ka HRC60, pono e hoʻokō koke ʻia ka mālama dehydrogenation ma hope o ka mālama ʻana i ka ʻili, i ʻole e haki nā ʻāpana kila i loko o kekahi mau hola.

Hoʻopili

E pili ana iā mākou

* Hōʻike ke kiʻi ma lalo nei i nā incoterms kālepa like ʻole.E ʻoluʻolu e koho i kāu makemake.

HUA KUAI HOT

Pono mua, palekana palekana

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9 Kiʻi Hōʻikeʻike](http://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-1.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](http://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-1-300x300.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](http://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-3-300x300.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](http://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-4-300x300.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](http://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-6-300x300.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](http://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-5-300x300.jpg)