DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9

DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9

wehewehe

AIKIPane

AIKIHua'ōlelo

AIKIHāʻawi

MAKAUKAU E HOOKAPU

10000+ SKU i loko o kahi waihona

Hāʻawi mākou i nā mea RTS:

70% nā mea i hāʻawi ʻia i loko o 5 mau lā

80% nā mea i hāʻawi ʻia i loko o 7 lā

90% nā mea i hāʻawi ʻiai loko o 10 lā

Nā kauoha nui, e ʻoluʻolu e kelepona i ka lawelawe mea kūʻai aku

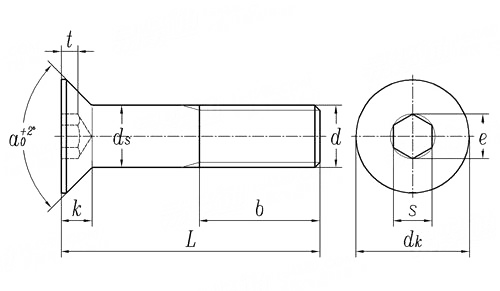

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Nominal | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Nominal | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Nominal | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Nominal | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

wehewehe kikoʻī

ʻO nā mea hoʻopaʻa ikaika kiʻekiʻe e hana i ka crispness i ka wā i hoʻopaʻa ʻia.Pono ka nānā kūikawā.

Hōʻike pinepine ʻia ka embrittlement hydrogen e ka haʻi lohi ma lalo o ke kaumaha.Aia nā pūnāwai kaʻa, nā mea holoi, nā ʻili, nā puna wai a me nā ʻāpana galvanized ʻē aʻe, i loko o kekahi mau hola ma hope o ka haki ʻana o ka hui, ʻo ka haʻihaʻi o 40% ~ 50%.I ke kaʻina hana o ka hoʻohana ʻana i nā ʻāpana cadmium-plated o kahi huahana kūikawā, aia nā ʻāpana ʻōpala, a ua hoʻoholo ʻia kahi pilikia kī kī aupuni a ua hoʻokumu ʻia kahi kaʻina dehydrogenation koʻikoʻi.Eia kekahi, aia kekahi mau hydrogen embrittlement ʻaʻole hōʻike i ka lohi ʻana o ka haki ʻana, e like me: electroplating hanger (steel wire, copper wire) ma muli o nā manawa he nui o ka electroplating a me ka pickling plating, ʻoi aku ka koʻikoʻi o ke komo ʻana o ka hydrogen, ʻike pinepine ʻia i ka hoʻohana ʻana i kahi paʻi. hiki mai ke ano hakihaki;ʻO ka mandrel o kahi pū pana, ma hope o kekahi mau manawa o ka chroming, hāʻule i ka honua a haki;ʻO kekahi mau ʻāpana kinai (ke koʻikoʻi kūloko nui) e pohā i ka wā pickling.Hoʻohana nui ʻia kēia mau ʻāpana me ka ʻole o ke koʻikoʻi o waho, ʻaʻole hiki ke hoʻohana hou ʻia e hoʻihoʻi i ka paʻakikī kumu ma o ka dehydrogenation.

ʻO ke kiʻekiʻe o ka ikaika waiwai, ʻoi aku ka nui o ka naʻau o ka hydrogen embrittlement.He manaʻo kumu kēia e pono e wehewehe ʻia e nā ʻenehana lapaʻau i ka wā e hōʻuluʻulu ai i nā kikoʻī kaʻina hana electroplating.ʻO nā kila me ka ikaika tensile σb>105kg/mm2 i koi ʻia e nā kūlana honua pono e hoʻokau ʻia i ke koʻikoʻi pre-plating a me ka mālama dehydrogenation post-plating e like me ia.Pono ka ʻoihana mokulele Farani i ka mālama dehydrogenation kūpono no nā ʻāpana kila me ka ikaika hua σs>90kg/mm2.

Ma muli o ka pilina maikaʻi ma waena o ka ikaika kila a me ka paʻakikī, ʻoi aku ka intuitive a maʻalahi hoʻi e hoʻokolokolo i ka naʻau hydrogen embrittlement o nā mea ma ka paʻakikī ma mua o ka ikaika.No ka mea, pono ke kaha ki'i huahana a me ka hana machining me ka paakiki kila.I ka electroplating, ua ʻike mākou ua hoʻomaka ka paʻakikī o ke kila a puni ka HRC38 e hōʻike i ka pilikia o ka haki ʻana o ka hydrogen embrittlement.No nā ʻāpana kiʻekiʻe aʻe ma mua o HRC43, pono e noʻonoʻo ʻia ka dehydrogenation ma hope o ke kau ʻana.Ke pili ka paʻakikī i ka HRC60, pono e hoʻokō koke ʻia ka mālama dehydrogenation ma hope o ka mālama ʻana i ka ʻili, inā ʻaʻole e haki nā ʻāpana kila i loko o kekahi mau hola.

Hoʻopili

E pili ana iā mākou

* Hōʻike ke kiʻi ma lalo nei i nā incoterms kālepa like ʻole.E ʻoluʻolu e koho i kāu makemake.

HUA KUAI HOT

Pono mua, palekana palekana